The car rearview mirror is an important part of car exterior parts, located on both sides of the car, is one of the most important exterior parts of the car. The rearview mirror of a car is a device used to allow the driver to observe the road conditions during driving, which can be said to be the driver's eyes. Automobile rearview mirrors are generally composed of mirror ring, base, mirror housing, bracket, rotating shaft, and other parts.

The parting line of the plastic part is on the R, and the R is on the fixed and movable mold respectively. In order to avoid the parting line appearance of the visual surface, special attention should be paid to making the core side 0.05-0.1mm smaller to avoid mismatch of the plastic part.

The fixed and movable die stop should be designed with precise positioning. Avoid dislocation of fixed and movable mold cores and prevent the mismatch of plastic parts.

Because of the sharp edges of the Auto rearview mirror housing mold setting and the mold core plastic material position, must be taken care of to protect it during the mold making. It is best to use opaque tape to protect it to avoid gaps during transportation.

When designing an oblique slider with a core pulling along the Z-axis, it is necessary to pay attention to the slope of the bottom surface of the front end of the oblique slider to be greater than or equal to the angle of the bottom surface of the oblique slider seat to avoid undercutting.

The design of the cooling lines and spring of the inclined slider must be parallel to the angle of the core pulling of the inclined slider to facilitate the processing of the inclined slider.

The bottom of the wear block at the bottom of the inclined slider should be designed to be straight, and the wear block should be protruding to avoid interference with the B plate and the stroke stop of the inclined slider when the inclined slider moves backward.

Since the oblique slide block must be installed with the fixed mold core to save the jaws, the slider needs to be designed for the mushroom head positioning, and the design of the craft screw is also necessary to facilitate the installation of the fixed mold core and the oblique slide block to save the jaws.

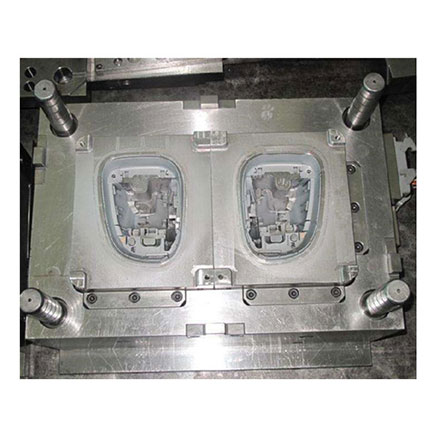

| Description | Automotive Rearview Mirror Cover Injection Mold |

| Plastic material | ABS |

| Mould cavity&core steel | P20,2738,718H,738H,NAK80,SKD61,E420,etc. |

| Mould weight (T) | 10T |

| Feeding System | Cold runner/ Hot runner |

| Hot runner brand | YUDO, HUSKYFISA, HASCO, MOLD-MASTER |

| Nos of Cavity | 1*2 |

| Manufacture time (day) | 40 days |

| Mould life | ≥500000 |

| Packing | Vacuum+plywood wooden box |

Green Vitality Industry Co., Ltd. has extensive experience in the design and manufacture of automotive rearview mirror housings. Automobile rearview mirror shell products require a high appearance. There is a large area undercut on the outer side of the plastic part and multiple undercuts on the inner side. There are many undercuts and a large area. This is a typical structure of automobile rearview mirror molds. The mold gating system adopts hot runner injection and adopts a 1-point open hot runner + cold runner + banana gate, and the material of the parts is ABS. The inner side of the mold adopts the lifter core-pulling structure, and the large-area undercuts adopt the lifter and straight lifter structure. After the mold is opened, the product and the runner are pushed out by the pusher. The pusher fixing plate is pushed by the injection molding machine through the cylinder and reset under the action of the reset rod. The cavity and core sides are designed with multiple sets of cooling lines. Each cavity is designed with 2 sets of cooling lines. The fixed and movable molds are 4 in and 4 out. The mold cooling line is designed to be consistent with the material flow direction. It adopts: "Straight water line + inclined type With the design form of waterway + well, the water inlet and outlet distances are roughly equal so that the product has a good cooling effect and appearance quality.

Pre-sale:

Green Vitality provides a good sales team for professional and prompt communication.

In-sale:

We have strong designer teams, will support customer R&D, If the customer sends us samples, we can make product drawings and do the modification as per customer request and send them to the customer for approval. Also, we will accord our experience and knowledge to provide customers with our technological suggestions.

After-sale:

If our product has a quality problem during our guarantee period, we will send you free to replace the broken piece; also if you have any issue in using our molds, we provide you professional communication.